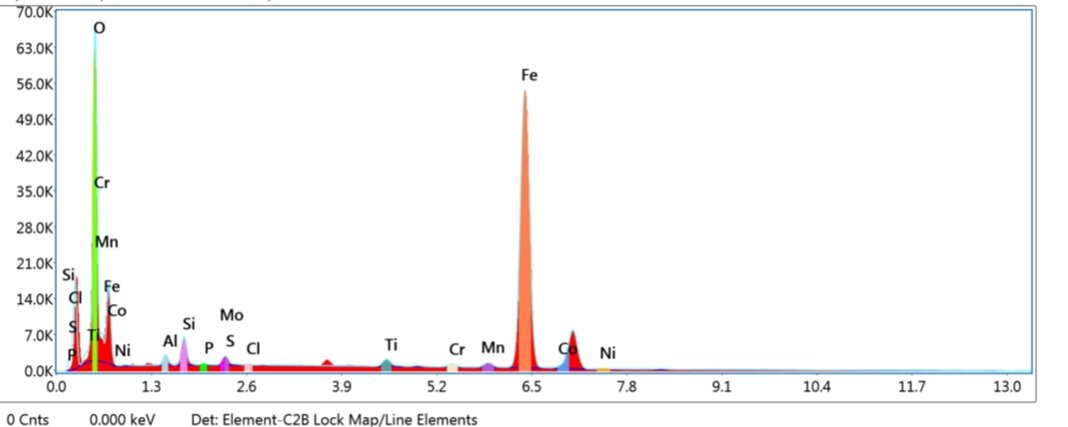

energy dispersive x-ray (EDS)

CHEMICAL ANALYSIS BY EDS

IVTS provides Energy Dispersive X-Ray (EDS) analysis for elemental composition of materials. EDS is a semi-quantitative x-ray technique used to identify the elemental composition of materials. Applications include particle identification, coating analysis, contaminant identification, and corrosion analysis.

The EDS lab silicon drift detectors are attachments to the Scanning Electron Microscopes (SEM). The imaging capability of the SEM identifies the specimen of interest, which can be instantly analyzed. The data generated by EDS consists of spectra showing peaks corresponding to the elements making up the true composition of the sample being analyzed. The speed of data collection combined with imaging of micro features makes EDS an ideal chemical analysis technique for forensic investigations.

EDS SPECTRA & ELEMENTAL DOT MAPPING

EDS peaks are generated due to the fundamental principle that each element has a unique atomic structure, which produce a unique emission spectrum. Peak intensities can be semi-quantified to general a weight percentage breakdown for each element detected.

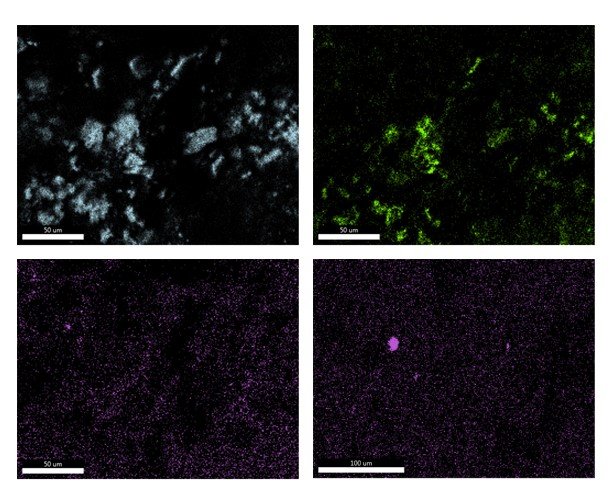

Elemental mapping of a sample and image analysis are also possible. The EDS analysis technique is non-destructive and specimens of interest can be examined with little or no sample preparation.

EDS Analysis Dot Map by Element

EDS CAPABILITIES

Qualitative and semi-quantitative elemental composition

Rapid identification of contaminants

Magnification – from 5x to 300,000x

Solid materials including metal, mineral and polymeric samples

Line Scan and Dot Mapping capability

EDS SPECIFICATIONS

ASTM E1508 - Elemental analysis by EDS

EDS SAMPLE REQUIREMENTS

Sample Size — up to 10 in. diameter and 3 in. in height.