metallographic Exam

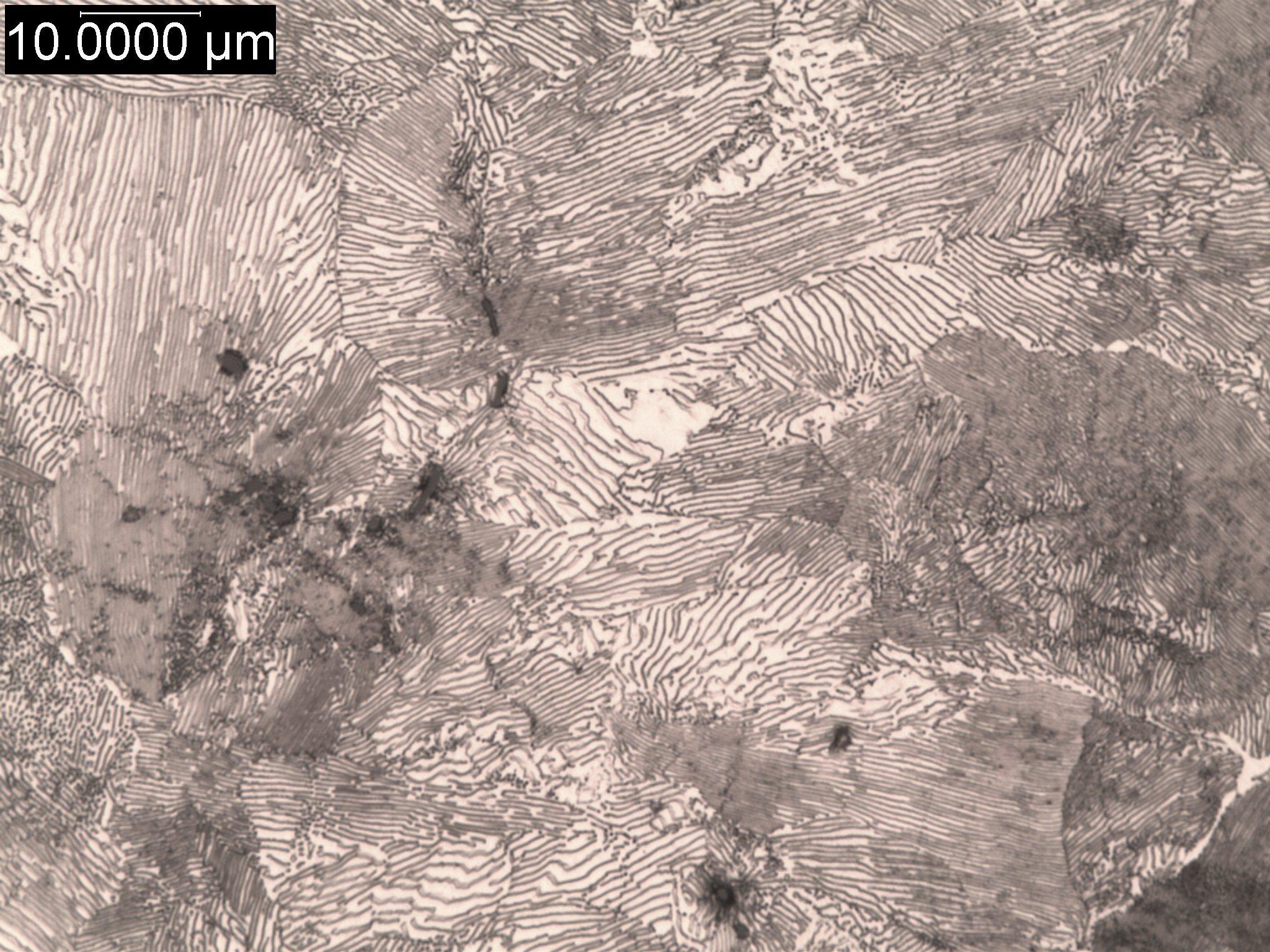

A metallographic exam utilizes inverted optical light for inspection of a material microstructure, grain sizing, and can provide clues to the origin of a metal failure. Our team of experienced metallurgists work with modern camera systems to capture material microstructures, flaws, and abnormalities, which may be critical to preventing future failures.

Metallographic examination is typically performed on polished cross sections, which may be etched to bring out the structure of the material by selectively corroding grain boundaries. Metallographic exam is often a critical tool for characterizing the extent of cracks and pits. Additionally, this inspection is used to characterize post processing changes due to casting, forging, machining, welding, heat treating and coating.

Metallographic examination is performed by using state of the art optical microscope equipped with a PAXcam™ III digital camera and image analysis software. Scanning electron microscope can be employed when higher resolution and micro-chemical analysis are required.

SPECIFICATIONS

ASTM E3 - Preparation of Metallographic Specimens

ASTM E112 - Grain Size

ASTM E45 - Inclusion Content of Steel

ASTM E1077 - Depth of Decarburization of Steel

ASTM E1268 - Degree of Banding or Orientation of Microstructures

ASTM A247 - Microstructure of Graphite in Iron Castings

ASTM E340 - Macroetching Metals and Alloys

ASTM E407 - Microetching Metals and Alloys

CAPABILITIES

Grain size analysis

Particle size/distribution

Coating thickness and case depth

Inclusion rating

Ferrite/pearlite percentage

Porosity

Grain flow pattern

Phase area fraction

Flake size classification

Nodularity

SAMPLE REQUIREMENTS

Up to 10″ diameter cross section; typically <1.25″ section